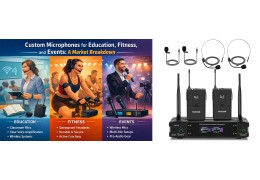

Custom microphones are transforming classrooms, gyms, and live events. From education microphone OEM solutions to...

Microphone Sensitivity, Pickup Pattern, and OEM Customization Explained

When it comes to designing high-performance audio equipment, understanding pickup pattern mic types, custom microphone sensitivity, and smart mic engineering decisions can make or break your product’s success. Whether you're developing an OEM product, upgrading studio gear, or managing a broadcast system, these technical elements directly impact clarity, directionality, and usability.

In this guide, we break down how pickup pattern mic, custom microphone sensitivity, and mic engineering choices affect sound performance—and how to customize them when ordering OEM microphones.

What Is Microphone Sensitivity?

Sensitivity refers to how well a microphone converts acoustic sound (your voice, music, ambient noise) into an electrical signal. In other words, it tells us how loud the output will be at a given sound pressure level.

Why Custom Microphone Sensitivity Matters

Every audio application has different needs:

• For ASMR recordings, you want high sensitivity to capture whispers and tiny sounds.

• For live concerts, lower sensitivity helps avoid distortion from loud instruments.

• For broadcast or headset mics, you need a balance that isolates the speaker’s voice while rejecting background noise.

When sourcing OEM units, custom microphone sensitivity lets you fine-tune signal output so the mic performs perfectly for your target use case.

Typical sensitivity is measured in mV/Pa (millivolts per Pascal) or dBV/Pa (decibels relative to 1 volt per Pascal). A higher number = a more sensitive mic.

How to Customize Sensitivity in OEM Mics

As a factory or OEM buyer, you can customize sensitivity by:

• Selecting a specific condenser capsule with the desired output.

• Adjusting internal preamp gain during mic design.

• Including limiting circuitry to manage peaks without distortion.

Smart mic engineering teams work with you during sampling to ensure the sensitivity matches your user environment—like quiet podcast studios vs. noisy stage events.

Pro tip: High sensitivity doesn’t mean better. It depends on how the mic will be used, and what kind of signal-to-noise ratio (SNR) is ideal.

Understanding Pickup Pattern Mic Options

A pickup pattern mic (also known as polar pattern) defines the area around the microphone where it best captures sound. This determines how well the mic isolates a voice from ambient noise or how much room sound it captures.

Common Polar Patterns:

Omnidirectional

1. Captures sound equally from all directions.

2. Best for: interviews, roundtable discussions, lav mics.

3. Pros: natural sound, no need for precise mic placement.

4. Cons: poor noise rejection, picks up everything.

Cardioid

1. Captures sound mainly from the front.

2. Best for: vocals, podcasts, solo instruments.

3. Pros: good isolation, common in handheld mics.

4. Cons: less ambient sound, placement matters.

Supercardioid / Hypercardioid

1. Even narrower front focus with slight rear sensitivity.

2. Best for: boom mics, film production, theater.

3. Pros: excellent directional control.

4. Cons: harder to position correctly.

Figure-8 (Bidirectional)

1. Captures from front and back, rejects sides.

2. Best for: two-person interviews, side-by-side setups.

3. Pros: excellent stereo potential.

4. Cons: rear noise is also captured.

Choosing the right pickup pattern mic is a foundational part of mic engineering. Your pattern must suit the environment and user behavior.

OEM Customization: Tailoring Pickup Patterns

When developing a microphone OEM product, you can:

• Choose fixed pickup pattern mic capsules (e.g., cardioid condenser).

• Use switchable capsules for multiple patterns.

• Engineer the housing and grille shape to support or shape directionality.

• Add DSP (digital signal processing) to digitally adjust virtual patterns.

Custom microphone sensitivity and pickup pattern mic features often work hand-in-hand. For example:

• A hypercardioid mic with high sensitivity is perfect for quiet film dialog in a noisy outdoor set.

• A low-sensitivity cardioid mic is ideal for handheld vocal use on stage.

The Role of Mic Engineering in Performance

At the heart of every OEM microphone project is mic engineering—the science of building, testing, and refining components to deliver performance for a specific application.

Key Mic Engineering Elements:

• Capsule selection: the brain of the mic, impacting frequency response and sensitivity.

• Housing design: impacts pickup pattern, wind rejection, and durability.

• Internal electronics: includes preamps, impedance matching, and power options (phantom, battery).

• Mounting hardware: clips, shock mounts, or boom integration.

• Connector types: XLR, USB, TRRS, custom OEM pins.

OEM factories often give you access to a catalog of components, and your mic engineering decisions define how those parts come together for real-world performance.

OEM Buyers: How to Specify Mic Sensitivity and Pattern

If you're not a sound engineer, it can be tricky to describe what you want in technical specs.

Here’s a guide to help:

Step 1: Define the Use Case

Are you building for:

• YouTubers?

• Singers?

• Public speakers?

• Instrument pickup?

• Mobile journalists?

Each one has different needs for custom microphone sensitivity and pickup pattern mic design.

Step 2: Describe the Environment

Is it:

• Indoors and controlled?

• Outdoor with traffic noise?

• Crowded events with live PA systems?

This helps the factory engineer in choosing:

• Noise rejection level

• Wind resistance

• Feedback control features

Step 3: Request Sample Testing

A reliable mic engineering partner will build multiple sample units with different specs, so you can field test and choose the best performer before going into mass production.

Matching Sensitivity + Pickup for Best Results

Let’s look at some smart combinations:

Use Case | Sensitivity | Pickup Pattern |

Interview (lapel) | Medium to High | Omnidirectional |

Stage performance | Medium | Cardioid |

Film boom mic | Medium to High | Supercardioid |

Podcast (solo) | Medium | Cardioid or Omni |

Outdoor ENG (news) | Low to Medium | Hypercardioid |

The goal is balance. For instance, if your pickup pattern mic is highly directional but your sensitivity is too high, it could still pick up distant noise and cause clipping.

That’s where professional mic engineering and OEM customization come in.

OEM Custom Branding and Functionality

Beyond the internals, OEM mic projects often include:

• Custom logos and housing materials

• LED indicators or mute buttons

• Integrated battery packs or USB-C ports

• Environmental sealing for weatherproof use

Every change affects performance. A plastic grille vs. metal can slightly alter high-frequency pickup. Mic color can even impact thermal performance if used outdoors.

Mic engineering isn't just internal—your choices in form and branding influence everything from sound quality to heat dissipation.

Quality Control and Testing in OEM Production

A pro OEM factory doesn’t just assemble mics—they measure every performance detail to ensure consistency. Here's what they typically test:

• Frequency response curve

• Output level at fixed sound pressure

• Polar pattern with test tones

• Self-noise level and SNR

• Durability (drop tests, moisture exposure)

When customizing pickup pattern mic types or custom microphone sensitivity, ask for lab data from your factory. That ensures your batch will meet expectations.

Wrapping It Up: Make Customization Work for You

At the intersection of pickup pattern mic, custom microphone sensitivity, and advanced mic engineering, you’ll find a powerful opportunity: the ability to craft gear that works exactly how your users need it to.

OEM customization isn’t just about slapping a logo on a product—it’s about building something that sounds right, feels right, and performs reliably.

Whether you’re building the next podcasting bestseller or scaling production for live performance gear, we help you turn ideas into working, tested, and branded microphones ready for market.

Need a custom solution? Contact our factory team for guided OEM development—from concept to capsule.

Top authors