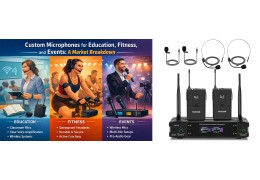

Custom microphones are transforming classrooms, gyms, and live events. From education microphone OEM solutions to...

MOQ and Lead Time: What to Expect When Ordering Custom Microphones

If you're sourcing audio gear for a brand, broadcast studio, or electronics distributor, chances are you’ve researched custom microphone MOQ, estimated your lead time OEM mic expectations, and compared timelines across factories before making a decision. Whether you're scaling up production or launching your first branded mic, understanding bulk mic orders and their timelines can save you major headaches—and money.

Let’s break down exactly what you need to know before hitting that order button.

What Is MOQ—and Why Does It Matter?

MOQ stands for Minimum Order Quantity. It’s the smallest number of units a manufacturer will accept for a production run of a custom microphone.

Why does custom microphone MOQ matter?

• It affects your total investment.

• It determines if a factory will take your order.

• It impacts production costs—lower MOQs often mean higher per-unit prices.

For example:

• A custom lavalier microphone may have a MOQ of 500 units.

• A wireless handheld mic system might start at 1000 units due to component sourcing.

Factors That Influence Custom Microphone MOQ

Every manufacturer calculates MOQ differently, based on:

• Component availability: Custom colors, capsules, or casings often require larger minimums.

• Labor intensity: More customization = higher MOQ.

• Factory capacity: Larger operations may only accept large orders.

• Packaging requirements: Custom retail packaging can increase MOQ due to printing minimums.

If you're ordering through an OEM mic supplier, you might see flexible options based on your relationship or the factory’s current production schedule.

Here’s how to get the best deal:

• Ask if a lower MOQ is available for a simplified version of the mic.

• See if the factory has existing molds or parts you can piggyback on.

• Combine SKUs—for example, 500 black + 500 white units to hit 1000 MOQ.

If you're serious about bulk mic orders, a clear conversation about your goals and long-term scaling plans can open up more favorable terms.

What Is Lead Time?

Lead time is how long it takes from the moment you place your order to the day your mics are ready to ship.

The standard lead time OEM mic buyers experience is:

• Sampling: 10–20 days

• Production: 30–45 days after deposit and sample approval

• Shipping: 7–30 days depending on air or sea freight

So, from first inquiry to delivery, expect 6 to 10 weeks total—sometimes more during busy seasons.

Factors That Affect Lead Time OEM Mic

Lead time is rarely fixed—it shifts depending on:

• Customization level: Unique molds, colors, or branding elements take more time.

• Material sourcing: Special components or imported parts may delay production.

• Factory load: Busy periods (pre-Q4, music festival season) increase lead times.

• Approval delays: Waiting on final confirmation for samples, artwork, or payment can push back the calendar.

Smart buyers avoid surprises by padding their timeline. If your event or launch is date-critical, communicate that early and build in a 2-week buffer.

Planning Your First Bulk Mic Orders

If you’re new to bulk mic orders, here's what the process usually looks like:

1. Inquiry & Quotation

You send specs (mic type, quantity, customization needs), and the factory responds with:

• MOQ and per-unit cost

• Sample and tooling fees (if needed)

• Estimated lead time OEM mic

2. Sample Stage

• Factory builds a prototype (branded or blank)

• You test it and request any changes

• Once approved, you give the green light for mass production

3. Production

• Parts are sourced and manufacturing begins

• QC and batch testing is conducted

• You’re updated with photos or videos of production milestones

4. Final Payment & Shipment

• Once ready, you pay the final balance

• Mics ship via your chosen method (air express, sea, rail)

5. Delivery

• You receive your bulk mic orders and check inventory

• Feedback and follow-up support begins (often leading to reorder)

How to Reduce Your Lead Time OEM Mic

Want your order faster? Here’s how to speed it up:

• Choose stock components instead of custom ones.

• Approve samples quickly—don't sit on them for a week.

• Confirm artwork, packaging, and SKUs in advance.

• Communicate clearly—keep emails direct and timely.

• Avoid holiday crunches—order before Chinese New Year, Black Friday, or back-to-school season.

If you're working with a professional factory, their internal systems are usually optimized already—but how you engage with them can make the timeline faster or slower.

Understanding Costs and MOQ Breakpoints

The higher your custom microphone MOQ, the lower your per-unit cost.

Here’s a sample cost curve:

Quantity Per Unit Price

500 pcs $19.80

1000 pcs $17.50

3000 pcs $15.20

5000 pcs $13.00

This sliding scale rewards volume, but make sure you balance:

• Inventory risk (do you have the space and capital?)

• Sales velocity (how fast will they move?)

• Version updates (are you planning a new model soon?)

If you're new, start at the lowest MOQ that includes full branding. Then scale up as orders grow.

Branding and Packaging Options

Most factories offer full OEM customization including:

• Logo printing (pad, laser, UV)

• Custom mic grill or casing colors

• Molded buttons or screen layout

• Retail packaging: boxes, hang tags, inserts

Note: Custom packaging often has a separate MOQ (usually 1000–2000 units). Ask if your factory can store extra packaging for future bulk mic orders.

And always request a packaging mockup during the sample phase—it’s easier to adjust layout now than after production.

Communication Is Everything

Here's how to keep your custom microphone MOQ and timeline on track:

• Use clear file names and document labels (e.g., “Final_Logo_Black_v3.ai”)

• Send consolidated updates instead of piecemeal emails

• Ask for weekly progress reports with photos/videos

• Set shared milestones: sample approval, tooling finish, packaging proof, etc.

And most importantly: work with a manufacturer that communicates proactively and transparently. A factory that ghosts you after deposit is never a good sign.

Common Mistakes to Avoid

Avoid these errors when planning your bulk mic orders:

• Assuming MOQ is negotiable without trade-offs

• Forgetting to confirm all branding elements during sample stage

• Paying late and expecting no timeline delay

• Underestimating customs clearance time

Bonus tip: If your order is urgent, ask about expedited lead time OEM mic options. Some factories offer priority production lanes for a fee.

Final Thoughts

Ordering custom microphones is an exciting step—whether you're launching a new product line, stocking up for live events, or entering the OEM audio space. But knowing your custom microphone MOQ, preparing for realistic lead time OEM mic conditions, and structuring your bulk mic orders smartly will save you costly delays and ensure a smooth production experience.

Our factory has helped brands, artists, and electronics companies scale custom audio hardware from 500 to 100,000 units—and we can help you navigate the full process from first sample to final shipment.

Contact our team today to get your quote, production timeline, and custom roadmap built around your specific needs.

Let’s build a mic that speaks for your brand.

Latest comments